Weigh Scale Repairs and Calibrations

Weighing instruments play an important role in most businesses. Commercial weighing scales come in a broad range of choices that are used for different applications, such as bench scales, lab or analytical scales, counting scales (as shown above), shipping scales, equipment scales and the more rigorous floor and truck scales.

Bench Scales

Bench scales are platform scales designed to provide best measurement while offering shock, static and overload protection. When excessive weight placed on the bench scale, it is designed to protect the load cell by absorbing the spring. General weighing applications include shipping, check weighing, filling, food processing and field testing of materials.

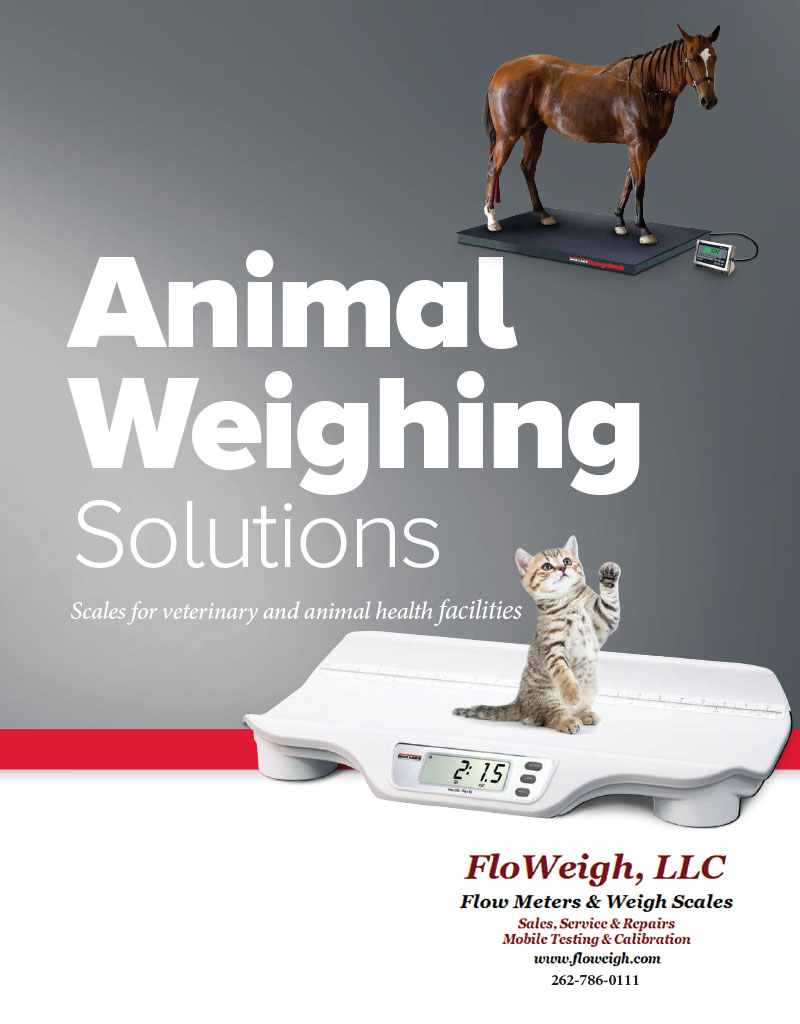

Animal Scales

Accurate weight measurements are critical for dosing animals with medication. Having a high-quality, well-maintained scale reduces the risk of overdosing that can result from weight data errors or estimations.

Features specific to animal scales include movement compensation for active patients, low profile design for easy access, and durable plastic surfaces for quick cleaning.

Floweigh carries a wide range of Rice Lake Weighing Systems that are designed for the needs and challenges of your animal facility.

Heavy Duty Floor and Truck Scales

Truck Scales

Truck scales are weighing scales that are used to weigh loaded vehicles. The load carried by the vehicle is calculated by weighing the vehicle (both empty and when loaded). Also known as weigh bridges, they are usually mounted permanently on a concrete foundation.

Truck scales are used to obtain highly accurate measurements of heavy loads, such as trucks, construction equipment or large pieces of equipment. Truck scales are used in industries that manufacture or move bulk items, such as in mines or quarries, garbage dumps, recycling centers, bulk liquid and powder movement, household goods, and electrical equipment. When you need an efficient way to measure the flow of bulk goods in and out of different locations, truck scales are your best option.

Floor Scales

The floor scale is one of the most popular and reliable ways of weighing objects, like trucks, tools, machines, raw materials, and vehicles. Often built into the floor of a factory, machine shop, or warehouse, they can weigh extremely heavy and bulky objects, making it very crucial for a wide variety of industrial, manufacturing and warehouse settings.

Floor scales are the largest and most durable weighing machines among all weighing scales. Depending on the tasks required, the platform size can vary. Platforms are designed with a flat and wide surface to facilitate weighing heavy objects, up to several tons. While some floor scales are made of welded steel or aluminium, most floor scales are made of stainless steel to withstand rugged, tough conditions and to prevent corrosion.

Floor scales come in various models, sizes and capacities. Mobile floor scales equipped with handlebars and wheels enable end-users to transport the scale around a stockroom, factory, or production floor with ease. Industrial floor scales usually range from three to ten feet, but they can also be bigger to accommodate higher-capacity loads, with an average weight capacity of 10 tons.

On-Site Services for Scales and Load Cells

Scale calibration and load cell installation or repairs at your facility can be a cost-effective method of servicing your standards and measuring devices.

Advantages of On-Site Testing

- Minimizes equipment and production downtime

- Eliminates shipping costs and delays

- Eliminates shipment risks and inconveniences

- Increases flexibility of calibration scheduling

- Provides minimal interruptions to your business

- Witness calibrations being performed

- Consult directly with our calibration specialists

(Have all of your calibrations performed at one time or schedule various calibrations throughout the year)

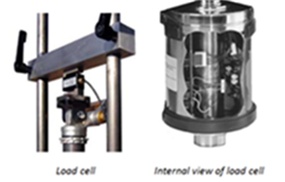

Load Cells

Load cells have sensors that measure weights. Periodic calibration of the load cell sensors will ensure that Load, Torque and Pressure Sensors are performing at optimal levels. If the load cells have been properly installed and recalibrated periodically, accuracy can be maintained within tolerance limits.

The service cycles will vary due to the number of variables involved, such as application environments and frequency of usage. An action plan must incorporate the usage to ensure that the load cells receive timely recalibrations as part of the overall maintenance schedule.

A vast number of load cell designs have evolved over the years. Today’s design uses strain gauges for the sensing element: either foil or semiconductor.

- Foil Gauges are used in most load cell designs because they have the largest choice of different types. Their strain gauge patterns provide measurement of tension, compression and shear forces.

- Semi-Conductor Strain Gauges are only available in a small number of patterns, but are extremely small and have large gauge factors. Due to these properties, they provide larger outputs for the same given stress and are typically used for miniature load cell designs.